21st Century Kinematics: NSF Workshop

I am pleased to provide the presentations from the 2012 National Science Foundation Workshop on 21st Century Kinematics. These presentations provide insight to the challenges and opportunities for research in mechanical systems and robotics.

The NSF Workshop on 21st Century Kinematics at the 2012 ASME IDETC Conference in Chicago, IL on August 11-12, 2012 consisted of a series of presentations and a book of supporting material prepared by the workshop contributors.

The book is available at amazon.com: 21st Century Kinematics–The 2012 NSF Workshop.

And here are the presentations given at the workshop.

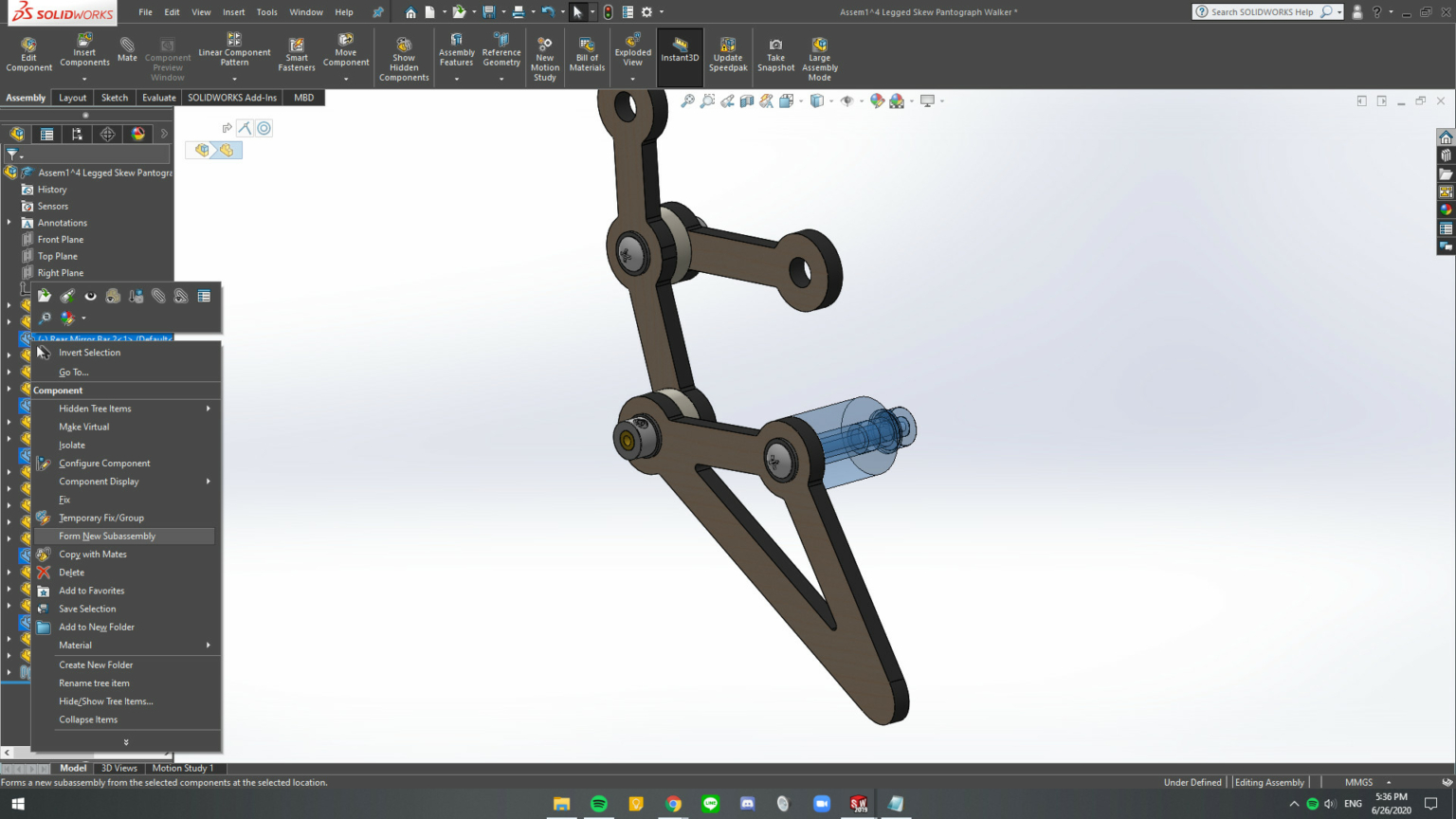

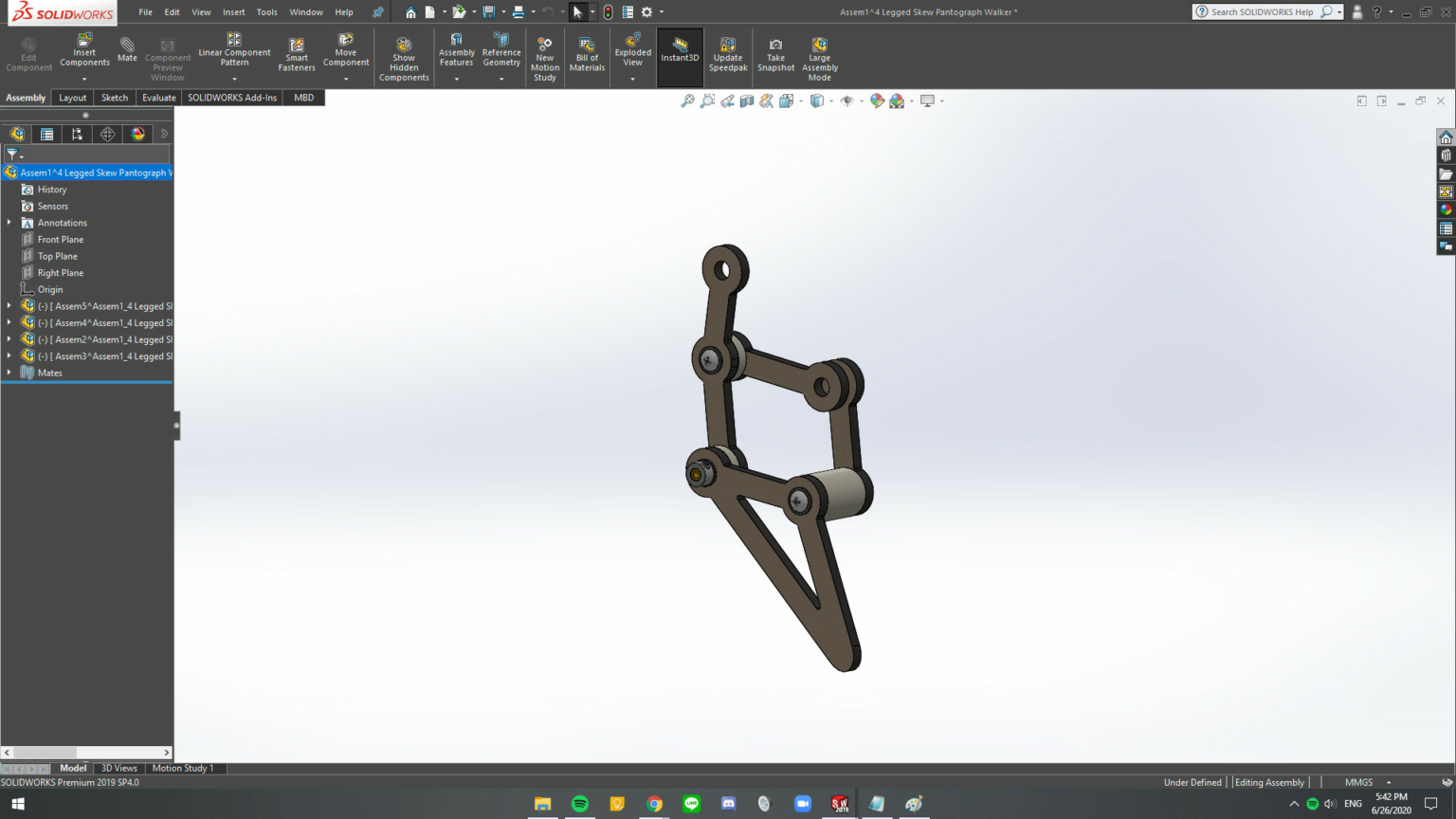

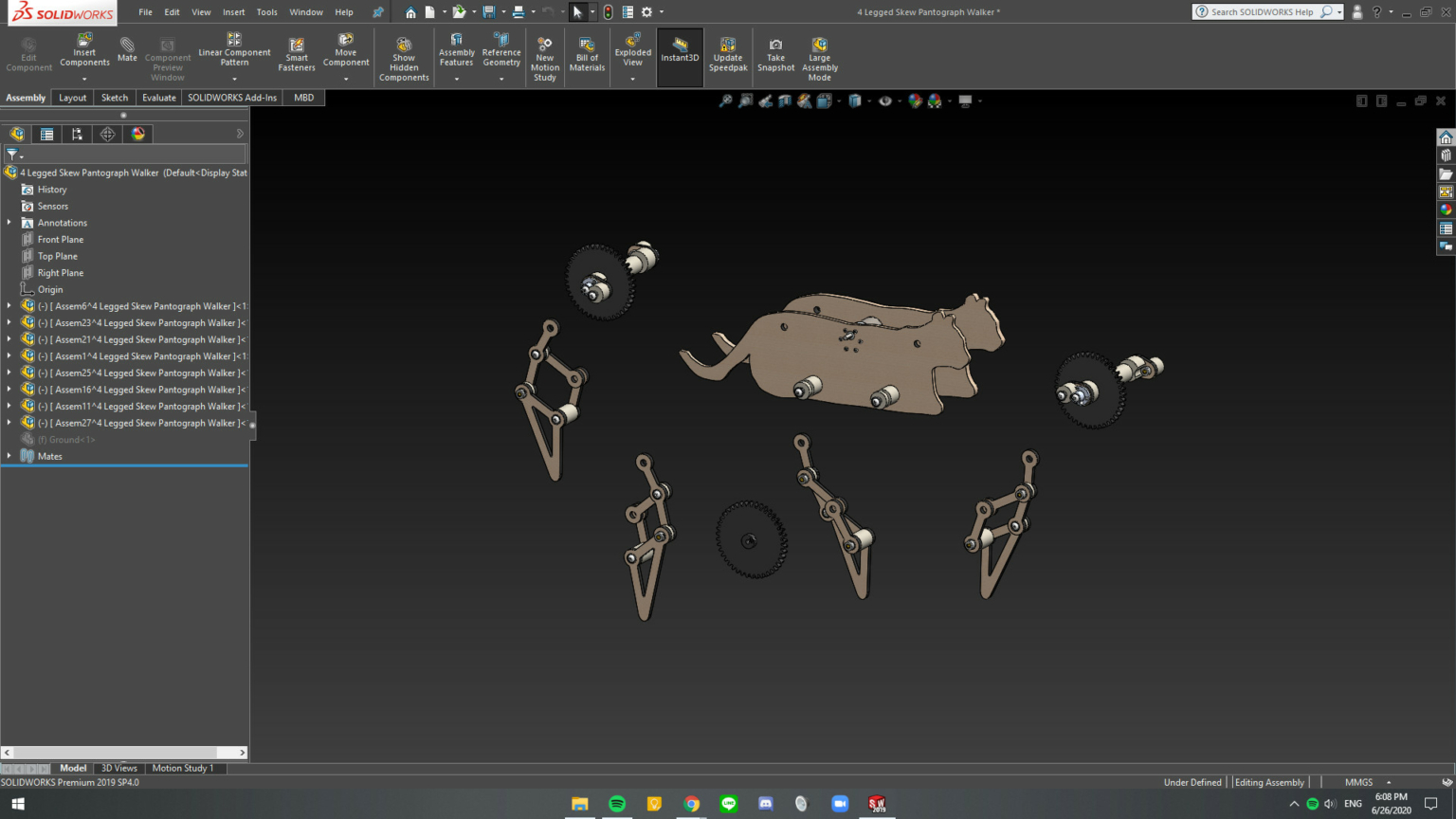

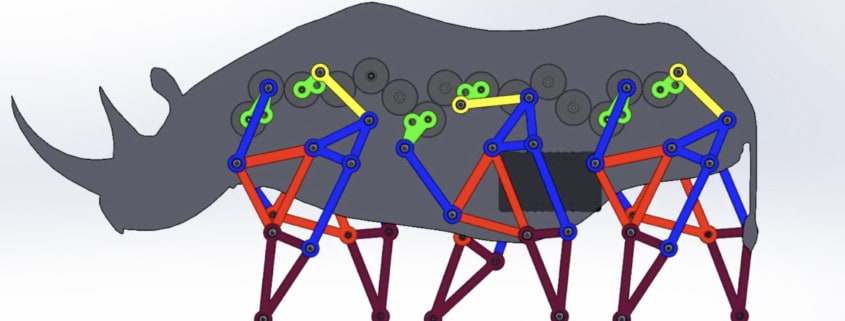

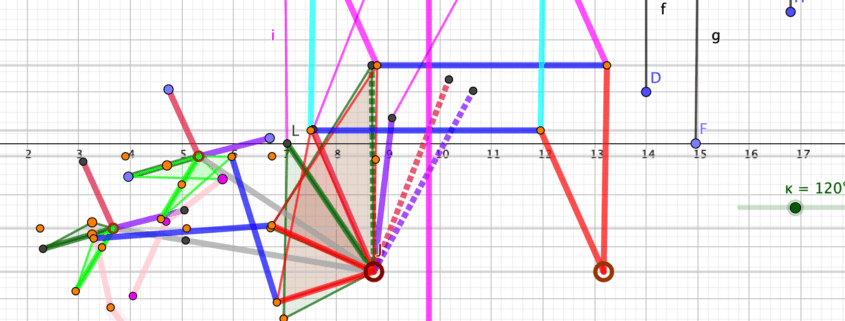

- Computer-Aided Invention of Mechanisms and Robots. J. Michael McCarthy, Professor, University of California, Irvine.

- Mechanism Synthesis for Modeling Human Movement Vincenzo Parenti-Castelli, Professor, University of Bologna.

- Algebraic Geometry and Kinematic Synthesis. Manfred Husty, Professor, University of Innsbruck.

- Kinematic Synthesis of Compliant Mechanisms. Larry Howell, Professor, Brigham Young University.

- Kinematics and Numerical Algebraic Geometry. Charles Wampler, Technical Fellow, General Motors Research and Development.

- Kinematic Analysis of Cable Robotic Systems. Vijay Kumar, Professor, University of Pennsylvania.

- Protein Kinematics. Kazem Kazerounian, Professor, University of Connecticut.

- Development of Fast Pick and Place Robots. Jorge Angeles, Professor, McGill University.

- Kinestatic Analysis of Mechanisms with Compliant Elements. Carl Crane, Professor, University of Florida.

It seems time to consider another similar workshop for 2022.

MDA Press

MDA Press MDA

MDA

MDA Press

MDA Press

MDA

MDA MDA

MDA MDA

MDA

JMM

JMM