Eight Legs, Two Motors and a Lot of Personality

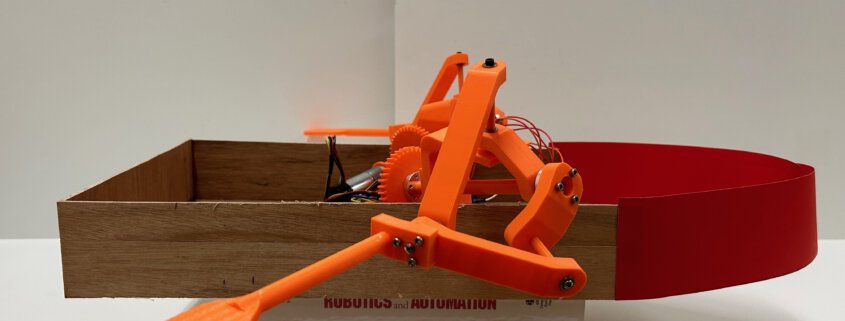

Please take a look at the videos demonstrating these Robot Walkers. Our study of minimal actuation for walking robots has lead to pairs of specialized leg mechanisms at each of four corners of the walker, eight in all. The robot is steerable with two separate drive motors, that is each side has four leg mechanisms connected through a gear train to a motor. This is a lot of moving parts, but the result is remarkable.

All of these robot walkers respond to commands from an infra-red remote control. They can go forward and backwards, speed up and slow down, turn right and left, and even spin in place.

It was a pleasure working with students on these projects. Their creativity and enthusiasm is fun to be around.

Stegosaurus Walker: This first video shows the Stegosaurus Walker designed and built by the team of Cristian Albrektsen, Itzel Montoya, Matthew Reber, John Williams, and Megan Yang. Select this link or the image.

The Grinch Walker: This second walker captures the Grinch Who Stole Christmas at the moment he brings the toys back to Whoville. It was designed and built by Melissa Lepe, Esteban Ruiz, Sebastian Petcu, Purushotham Verma and Jasper Yao. Select this link or the image.

Tio de Nadal Walker: The third walker celebrates a Catalan tradition known as the Tio de Nadal, which is a magical log that delivers presents and warms the family. It was designed and built by Paula Simo, Lois Meira, Eudald Sangenis, and Marc Quiroga. Select this link or the image.

MDA Press

MDA Press MDA Press

MDA Press MDA Press

MDA Press MDA Press

MDA Press MDA Press

MDA Press MDA Press

MDA Press

MDA Press

MDA Press MDA Press

MDA Press