DNA Origami Mechanisms and Machines

Professors Carlos Castro and Haijun Su have developed what they call DNA Origami Machines and Mechanisms to pave the way for new small scale devices that could revolutionize medicine, manufacturing, and environmental sensing.

DNA Mechanisms made from links of relatively rigid dsDNA bundles joined by soft ssDNA strands have the potential to provide machines for molecular transport in bioreactors, targeting cancer cells for drug delivery, or even repairing damaged tissue.

Protein is an attractive material for machine construction because there is a huge range of naturally occurring protein-based molecular machinery, but it has been difficult to control proteins structures due to the multitude of complex amino acid interactions that govern protein folding. DNA, however, self-assembles by base pairing and base stacking interactions, natural processes that these researchers essentially “plug in to” to create, manipulate, and “tune” compliant structures. This has led to research on how to use DNA in machine design.

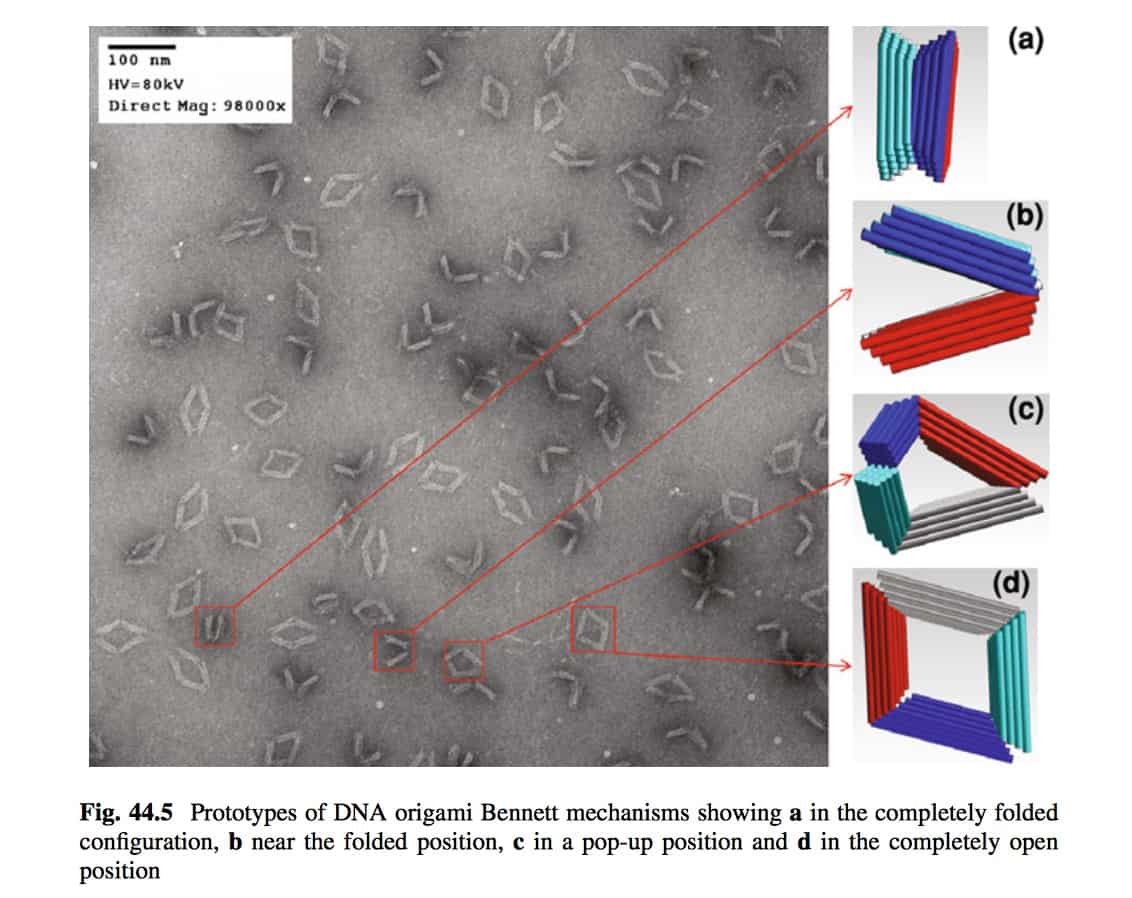

The recent development of scaffolded DNA origami has enabled the construction of nanoscale objects with unprecedented 3D structural complexity by self-assembly. To quote Professor Su’s paper, “We … locally bend bundles of double-stranded DNA into bent geometries whose curvature and mechanical properties can be tuned by controlling the length of ssDNA strands.” This demonstrates a mechanical model that predicts both their geometry and mechanical properties.

As Professor Su states, they are working to “provide a basis for the design of mechanically functional DNA origami devices and materials.” DNA origami mechanisms open an interesting frontier in machine design at the nano level. It is a continuance of mechanical progress that has been a part of engineering for centuries with a potential that until now has been merely the subject of science fiction.

References:

DNA Origami Compliant Nanostructures with Tunable Mechanical Properties: Lifeng Zhou, Alexander E. Marras, Hai-Jun Su, and Carlos E. Castro, Dec. 18, 2010

Design and Fabrication of DNA Origami Mechanisms and Machines, Haijun-Su, Carlos Ernesto Castro, Alexander Edison Marras, Michael Hudoba; Advances in Reconfigurable Mechanisms and Robots, 2012, pp. 487-500